Surface treatment

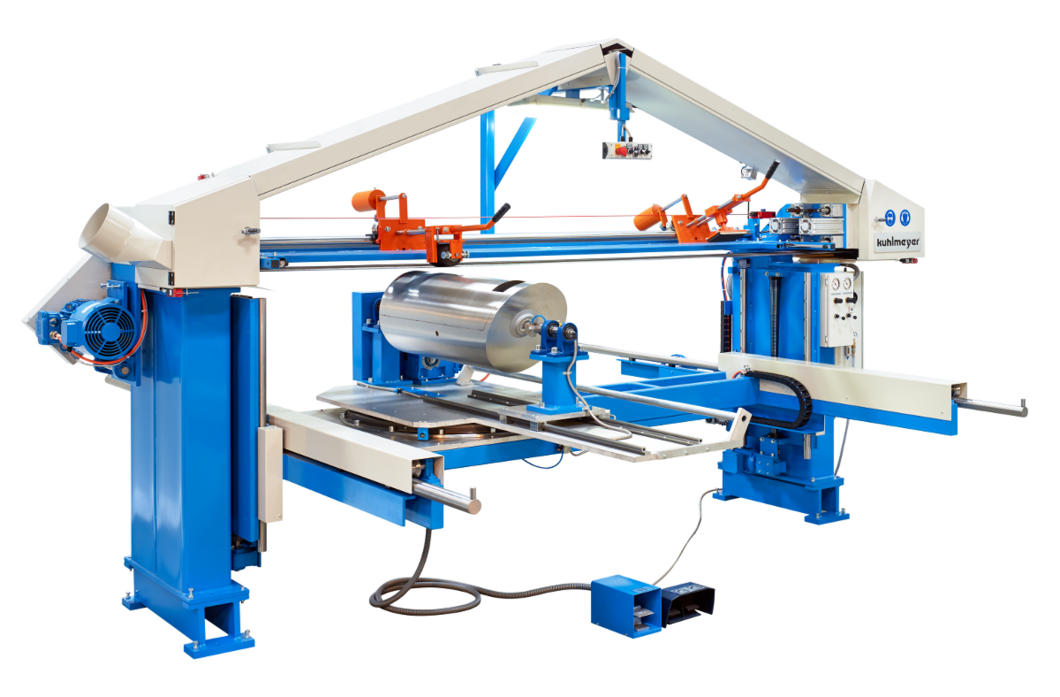

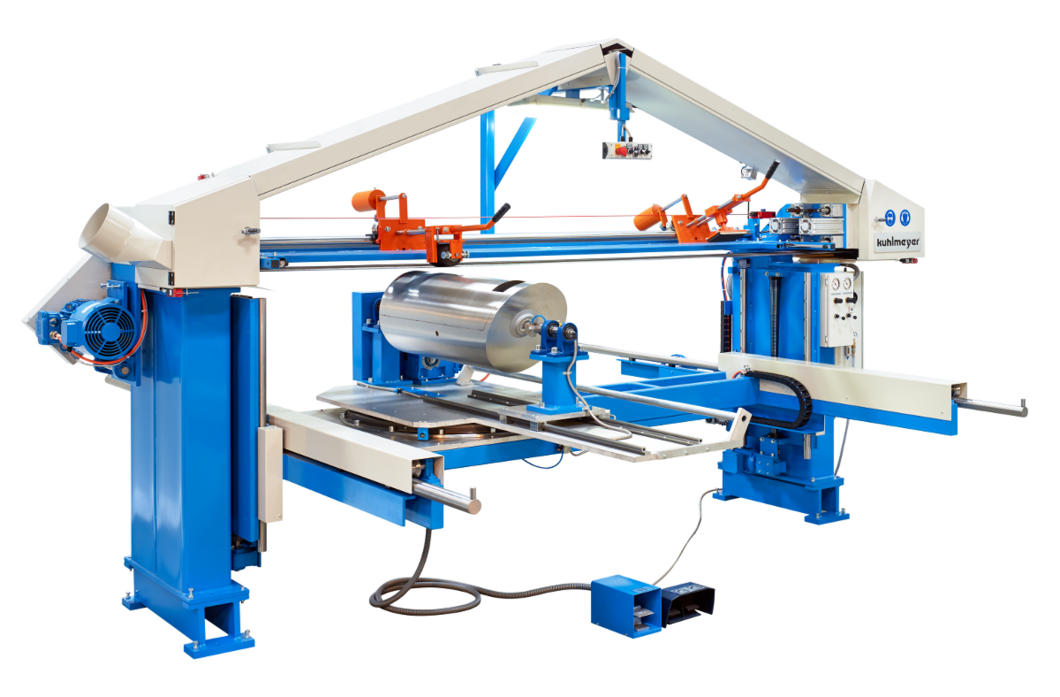

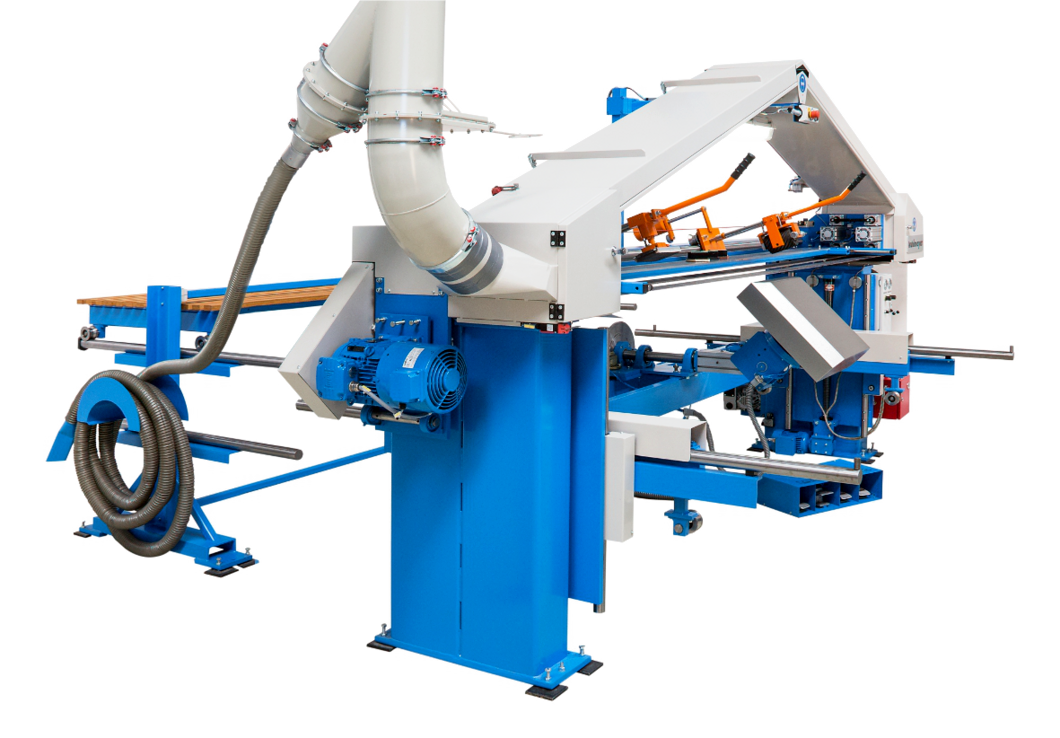

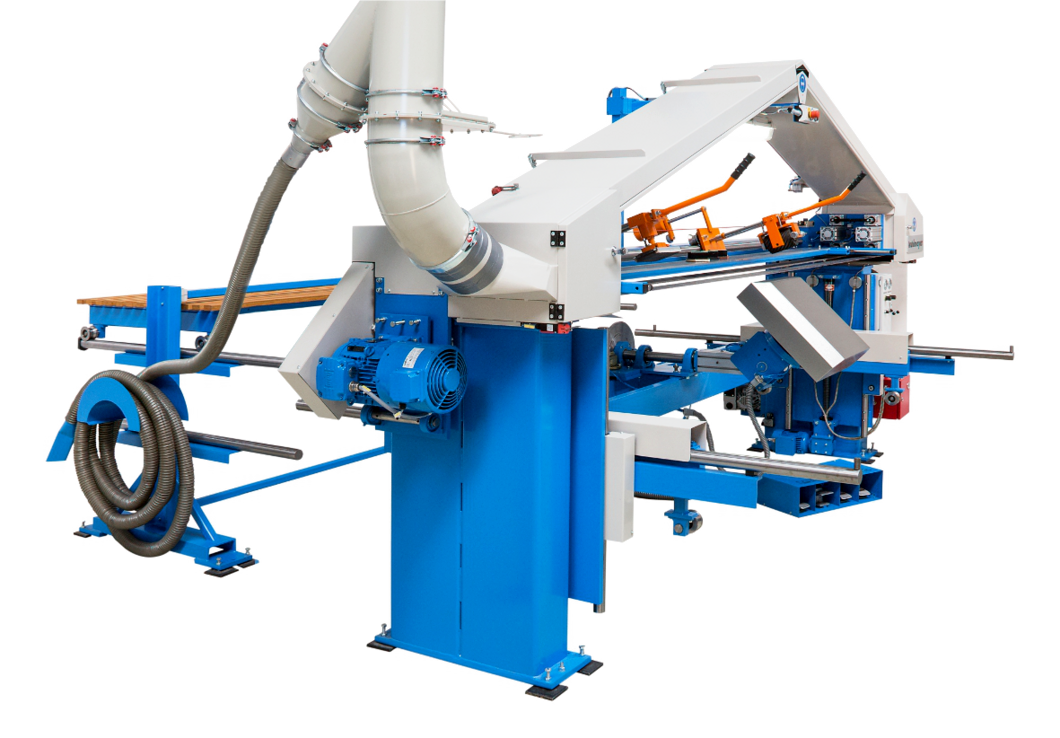

For perfect surfaces: The 2-belt grinding machine

Are you products lacking a very special finishing touch!

KITZMANN finishes components individually to suit your requirements, for example, in terms of the grain size and the direction of the finish.

A state-of-the-art 2-belt grinding machine is available to do this. Workpieces of any shape can be pre- and post-ground in a clamp with two belts running parallel to each other.

The workpiece handling equipment with vacuum clamping ensures the quick and accurate mounting of workpieces and their precise movement in 5 axes. The result is evenly ground surfaces with perfect edges, corner weld seams, contours and transitions.

The table dimensions are 3000 x 1000 mm. The corresponding additional mounts are available for larger workpieces.

Our technology - made in Germany

In addition to the surface treatment using the 2-belt grinding machine, we also offer you the following finishing options depending on the material and geometry:

- Glass bead blasting (aluminium and chrome-nickel steel)

- Lacquering according to RAL to suit the customer's requirements

- Decorative finishes for stainless steel components

- Pickling and passivation

- Powder coating according to RAL at the customer's request

- Galvanising

- Nickel plating

- Chromate conversion coating

- Electrolytic polishing

- Burnishing

We also perform the following treatments to optimise the metal properties:

- Stress-relief annealing

- All hardening processes