Automation

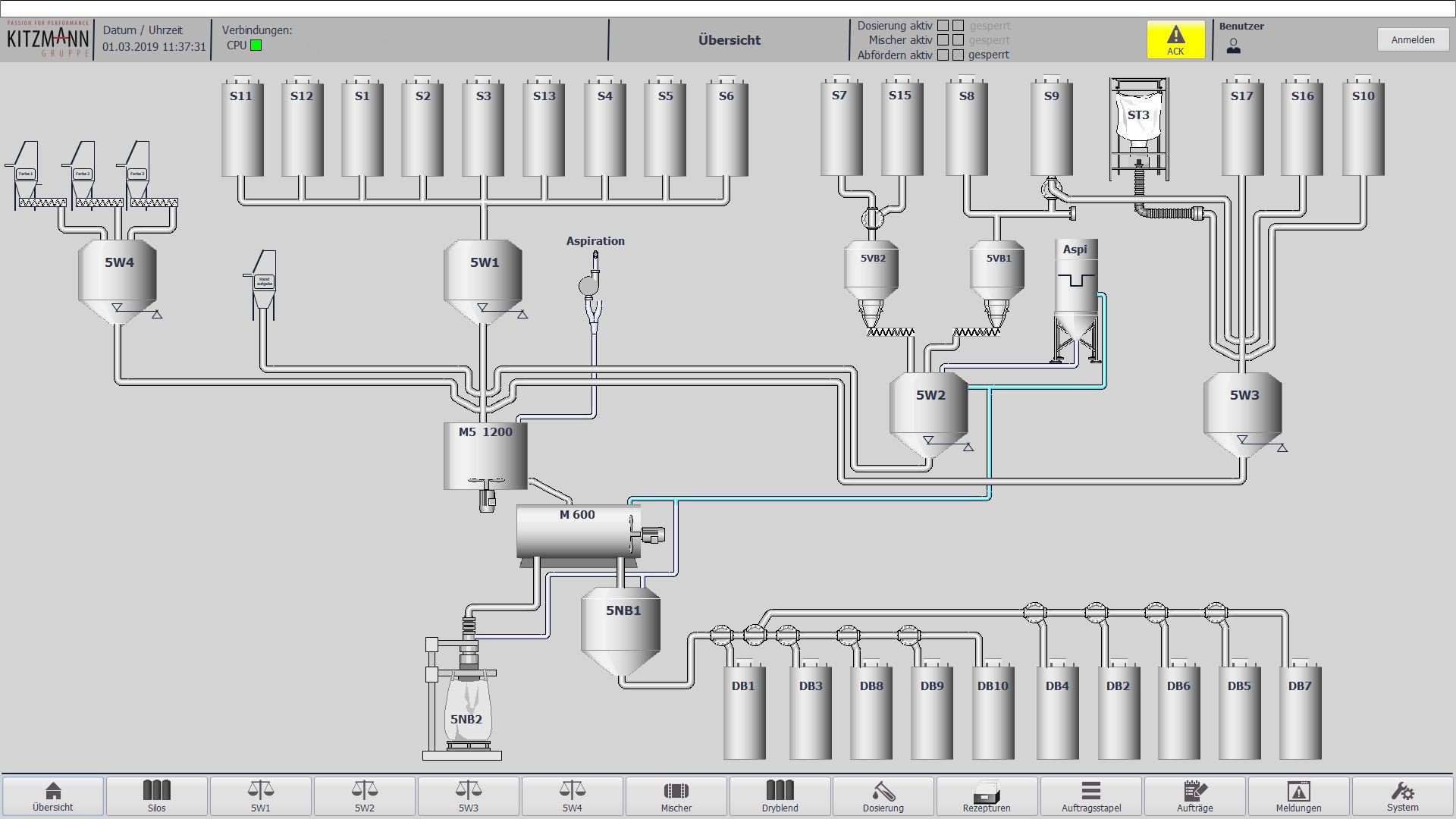

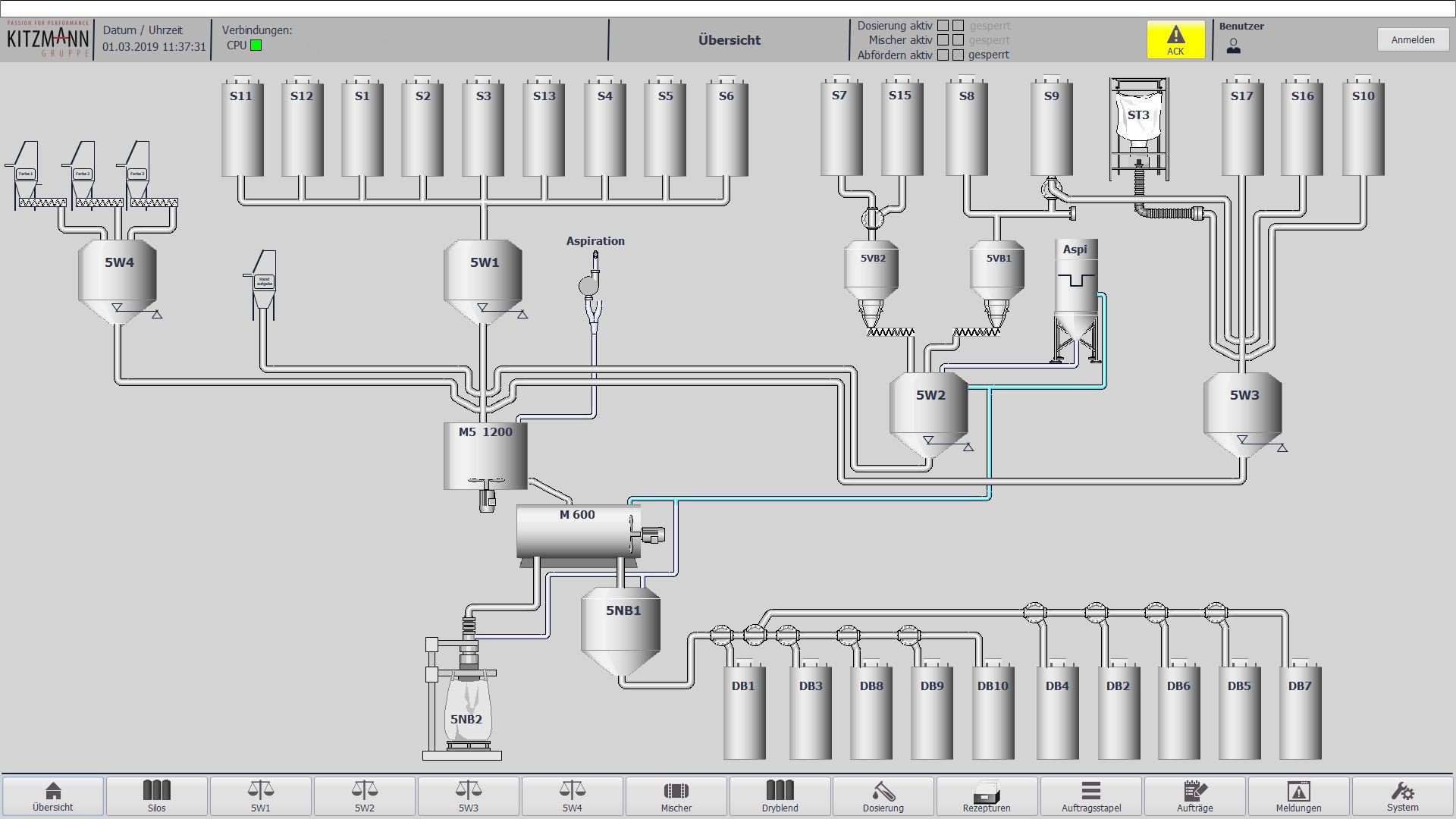

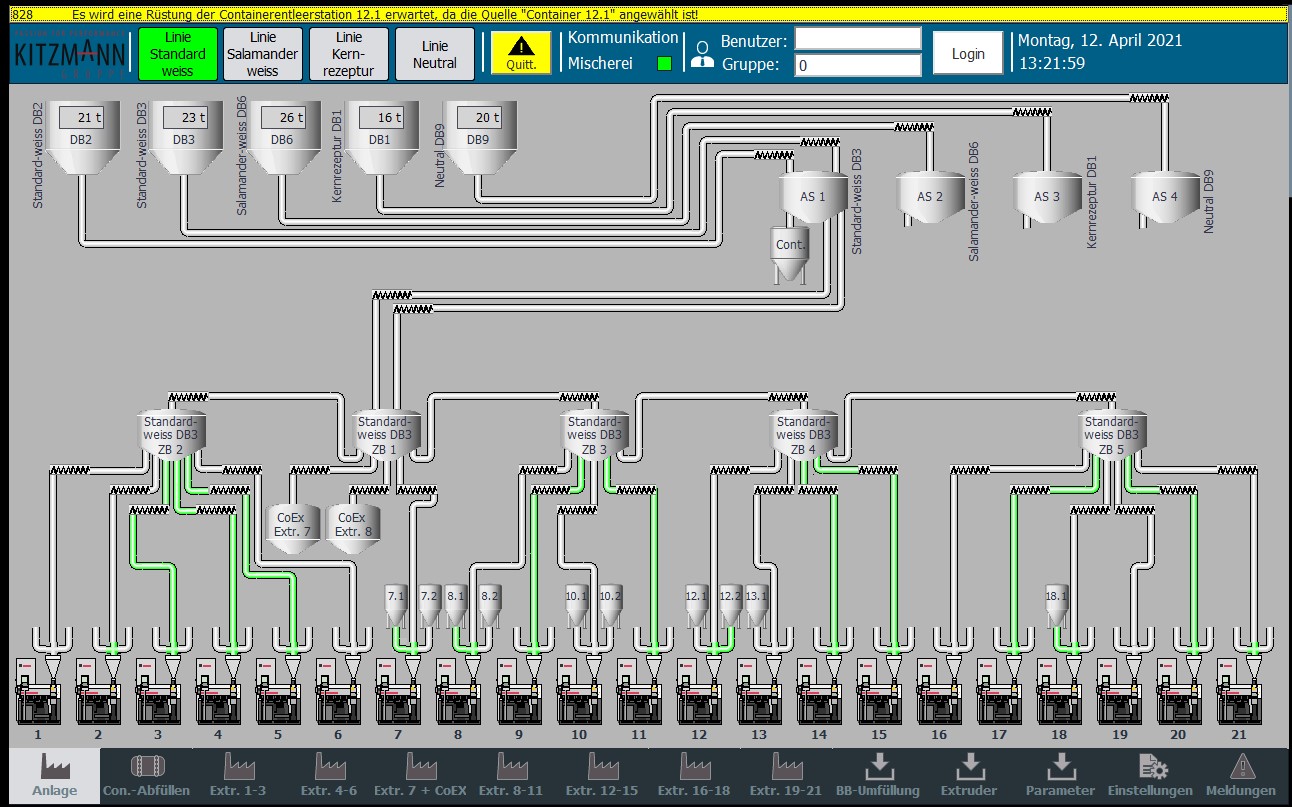

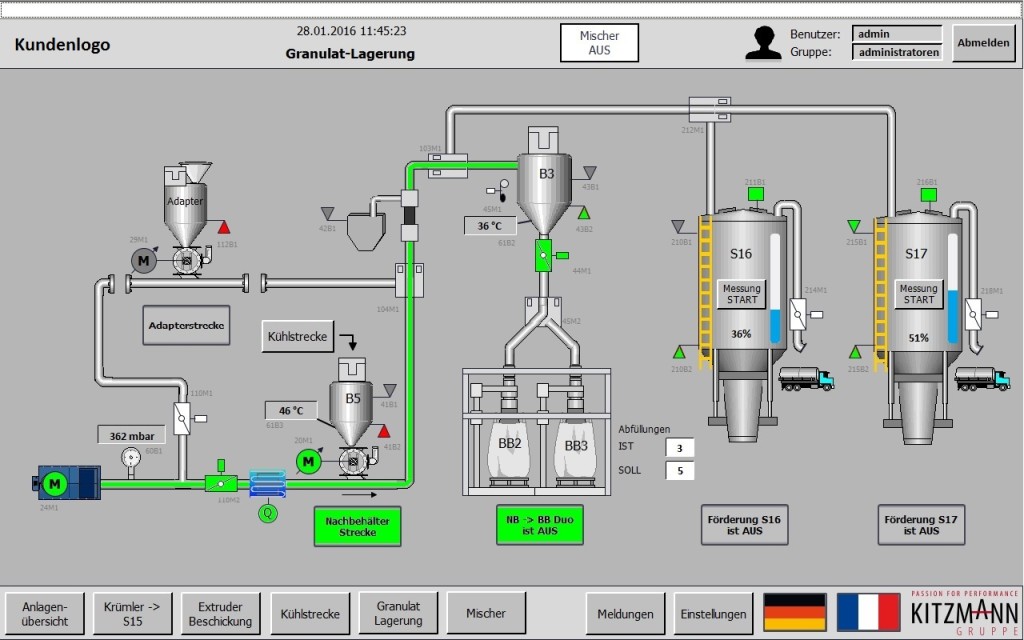

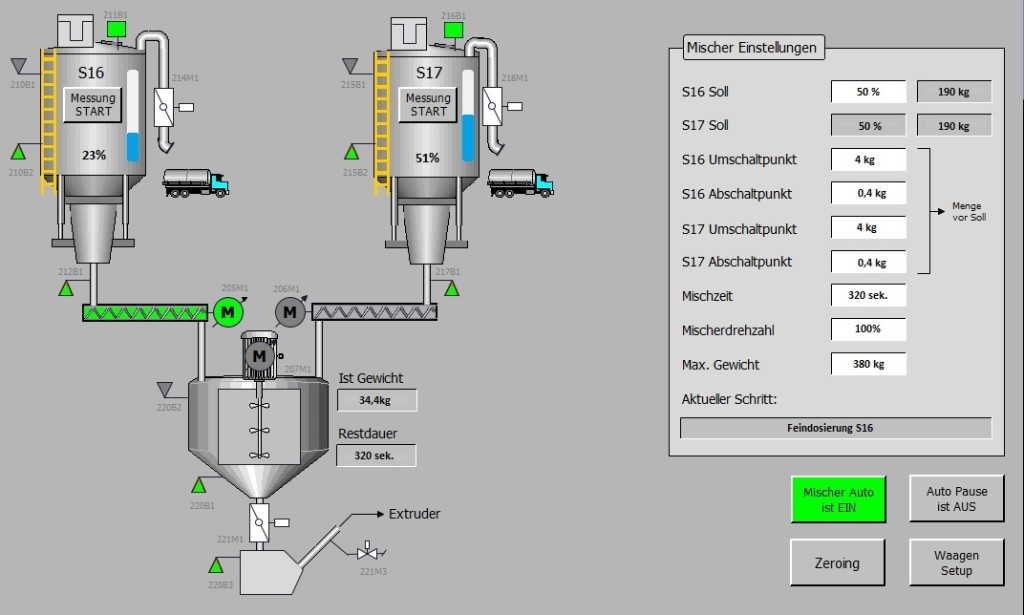

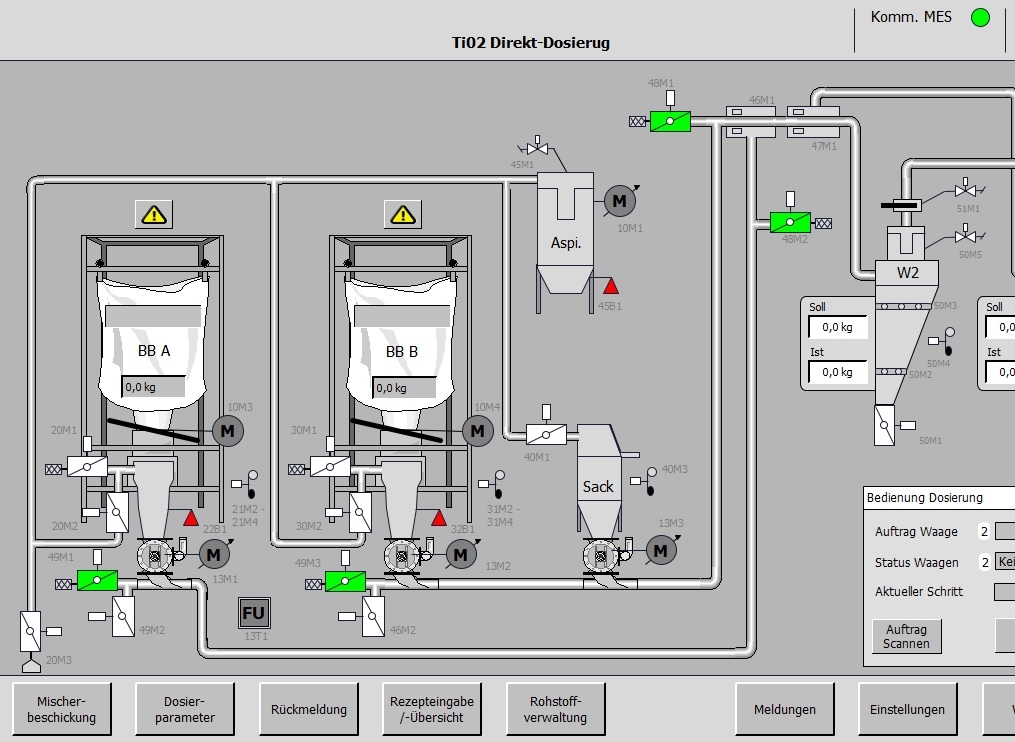

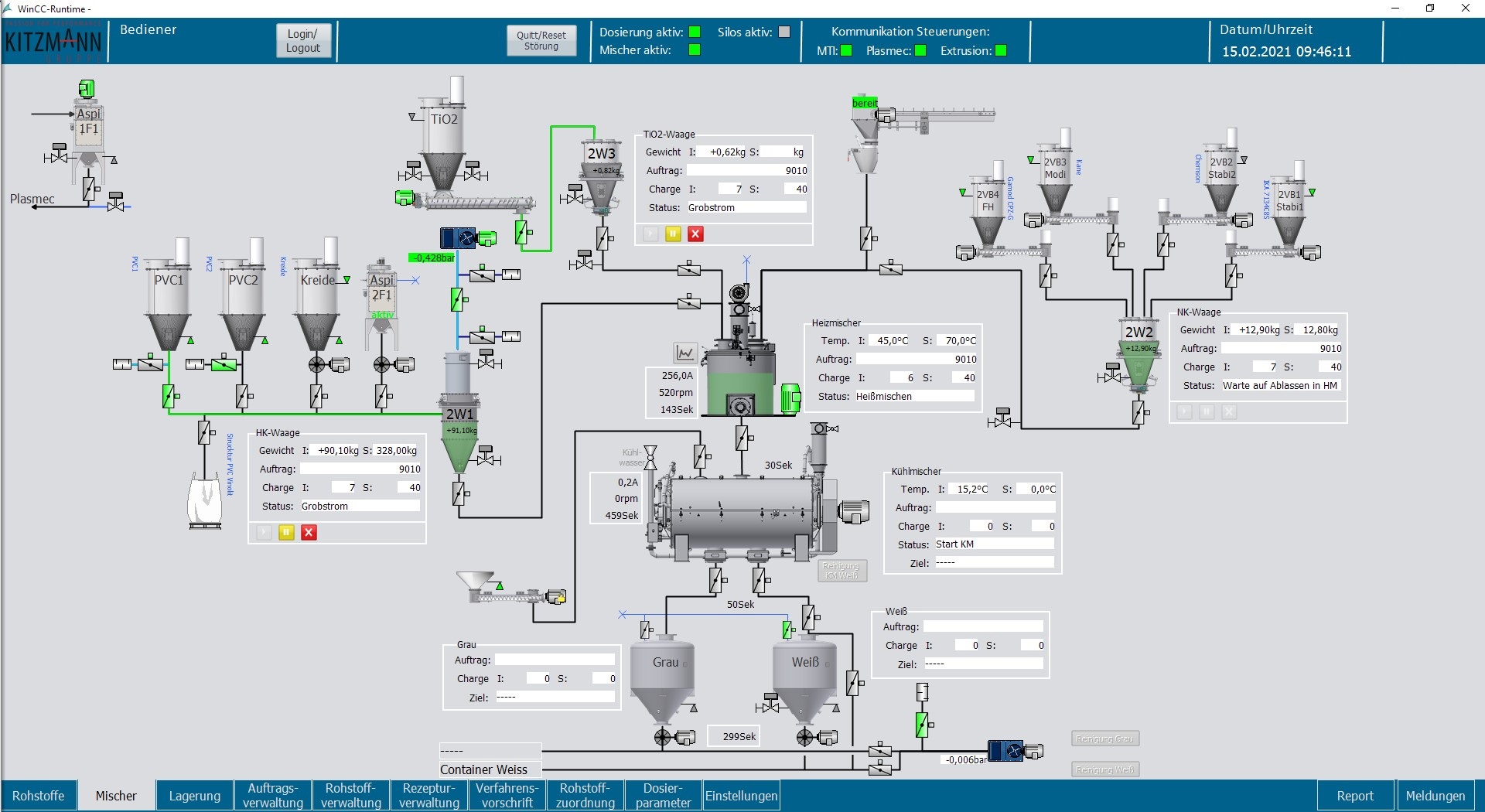

In line with our process engineering solutions, we are developing plant automation software solutions for maximum process safety using optimally coordinated control modules and intuitive user interfaces.

Your benefit for users, operators, handlers and operating companies:

- Reproducibility of dosing

- Consumption accounting for permanent quality assurance

- Associated optimisation of formulations

The automation range comprises the entire range from streamlined PLCs to complex, database-controlled and parameterisable control systems. This means that process control system from KITZMANN covers all levels of the automation pyramid from the input/output level to the connection to your ERP system.